Grounds crew creates diamond perfection

It takes teamwork and a long day of meticulous care to prepare Bryson Field for a baseball game.

This story is part of The Well’s series showcasing employees who work well together to further Carolina’s mission.

On a bright 68-degree afternoon at Boshamer Stadium, the Tar Heels and their opponent, N.C. A&T, have finished batting practice. A different team stands just off Bryson Field near third base, ready to spring into action.

It’s the grounds crew, and they have 30 minutes before the 4:03 p.m. first pitch to apply finishing touches to an infield they’ve spent most of the day perfecting. Their job is nearly done. No time for lollygagging.

As Boshamer’s PA system cranks out the last notes of Cody Johnson’s “’Til You Can’t,” crew leader Ryan Anderson, Boshamer Stadium facility and turf supervisor, thrusts his right arm through a coiled irrigation green hose and hoists it on his shoulder. Five crew members stand by him waiting for their cues to put their rakes, paint and machines to work.

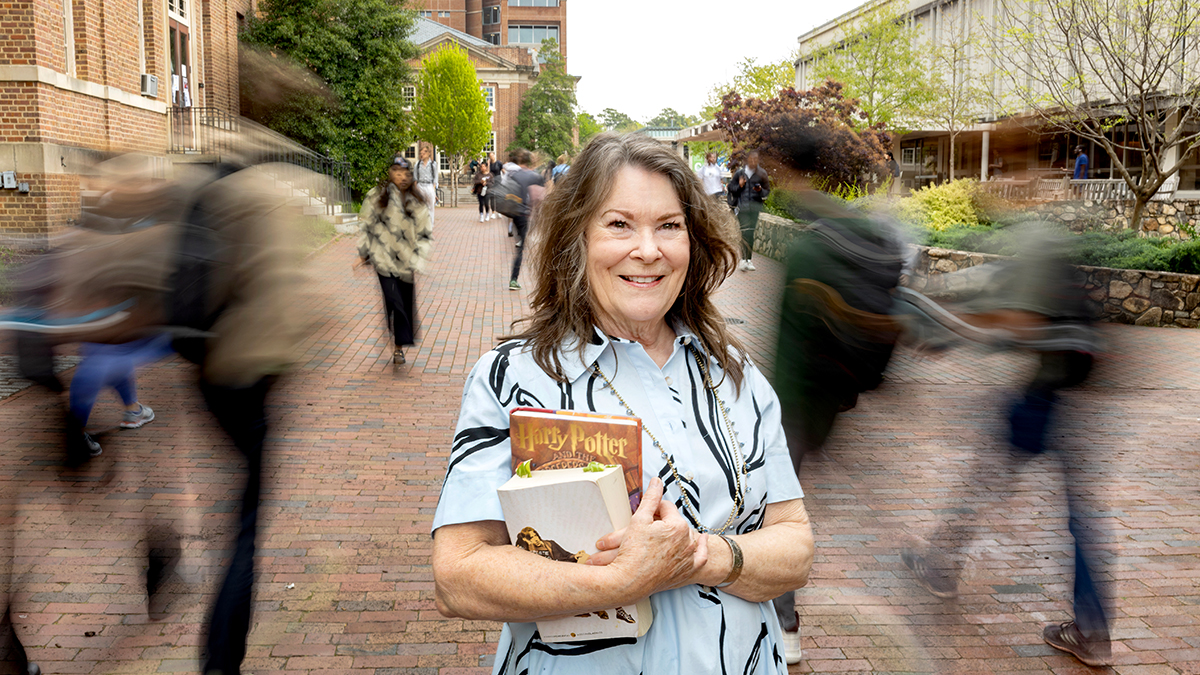

The crew rolls out from the third base side onto the infield, ready to set the game bases, drag and spray the surface and smooth out the transition from dirt to grass. (Jon Gardiner/UNC-Chapel Hill)

The men are part of the athletics department’s Grounds and Turf Management crew. Their work, which enables players to field balls that bounce true, move assuredly without injury and play their best, is essential — and part of why Boshamer Stadium is one of the finest collegiate baseball facilities.

The crew includes Sammy Jermane, Dorrance Field facility and turf supervisor; Nathan Josey, Shelton Field Hockey Stadium manager; Chris Rinebold, associate sports turf manager; Thomas Geer, Loudermilk Center director; Jon Wilson, an athletic grounds staff member; and Zach Carrothers, a temporary worker.

Their work is a marvel of efficiency, what organizational behavior experts call distributed expertise. Each sets about his tasks almost wordlessly, trusting each other to achieve the high standards they all strive for.

7:46 a.m.

Field preparation began nearly eight hours earlier, when Anderson arrived at his workshop behind left field. After planning the crew’s long day of field grooming, he spent 30 minutes push-mowing the infield grass, a blend of Bermuda and perennial rye. He next used a plate compactor to stabilize the DuraEdge “BlackStick Gumbo” Mississippi Delta clay at the pitcher’s mound and the batter’s boxes. “That’s so our pitchers can go out there with confidence and know that the mound beneath their feet will support them pushing off and landing,” he said.

Anderson checked the 6-inch-deep infield clay, topped with red, crunchy granules of kiln-dried calcine clay called conditioner. It holds moisture and creates a consistent playing surface. At 8:30 a.m. he criss-crossed the outfield grass on a riding mower to make a striped pattern.

As the morning sun ascends, Ryan Anderson tamps the clay on the pitcher’s mound. (Jon Gardiner/UNC-Chapel Hill)

9:58 a.m.

The crew arrived, stopping by the workshop to choose from neatly stored shovels, brooms, string trimmers and rakes, as well as lawnmowers, a ride-on blower, utility vehicles and bags of clay.

Carrothers checked clay moisture in the two bullpens, where pitchers warm up. He strives for perfect — what Anderson calls “cleat-in, cleat-out,” where players’ cleats don’t pick up clumps of clay and track them around the infield to affect the ball’s bounce. The technique is to stick a key or pocketknife into the clay and wiggle it to see if any adheres. “If dirt doesn’t break apart, that’s good moisture,” Anderson said.

Josey steered a frontline blower across the outfield and adjacent artificial turf to remove peanut shells, leaves, trash and any grass clumps, for aesthetics and to keep balls moving smoothly. Rinebold washed out the dugouts with a garden hose. At the shop, Carrothers scrubbed the practice bases and a set for the game with soap and a brush-equipped impact drill, then rinsed them with water.

Meanwhile, Anderson pulled a steel drag around the infield to bring conditioner to the dirt’s top layer. He used a steel lute rake to flatten out a tiny ridge of conditioner left by the drag. “Our infielders can have confidence that the ball is not going to bounce up and hit them in the face or the chest. They know where the ball is going,” Anderson said.

11:07 a.m.

Anderson gave the infield dirt, or skin, the day’s first watering to create cleat-in, cleat-out clay. “The most important thing for working a baseball field is the infield skin moisture,” Anderson said. “It shouldn’t be so hard that when they dive or slide on it, they rip pants or get a road rash. Too dry, it’s like concrete.”

With the first round of chores complete, the crew ate lunch together. Then, as if by instinct, they rose and began preparing for the pre-game batting practice.

They walked around the infield pulling 6-foot-wide brooms to dry the conditioner and prevent it from embedding in the top layer. That also creates insulation between the infield skin and the air above. Then they placed mats in front of home plate and around the bases to protect the grass and surface from repeated hits during batting practice. They set screens at bases and a portable batting cage at home plate to protect players and coaches. Anderson watered the infield to keep the moisture level up.

Around 1 p.m., done with phase one of the field prep, most of the crew left to check on other venues. Others went to the shop to clean and gas up utility vehicles and wash mowers.

Like a choregraphed troupe, the crew reassembled at 3 p.m., just as Carolina’s batting practice ended. They removed the screens, batting cage and all grass-saving mats except the one by home plate. N.C. A&T readied for brief fielding drills known as “in and out” to get used to the surface.

Go time

Boshamer Stadium fills with fans. First pitch is 30 minutes away. It’s go time.

The grounds crew applies the final touches, checking the mound, raking around bases, walking a steel drag down the baseline, putting down freshly cleaned game bases.

Josey, Wilson and Carrothers prepare to paint the first and third baselines, communicating with hand motions, as they’re up to 127 feet from each other. Jermane spools orange-chalked twine from home plate to the infield’s edge, then snaps it taut. Wilson checks the line before Josey pushes a cart equipped with a trigger-activated sprayer along it. The smell of paint wafts toward the dugouts.

At home plate, Carrothers and Wilson spray-paint a template to form the batter’s boxes. Josey eyes the result, nods and says “Yeah.” Then he bends down to coat home plate with “Game Day” brand paint until it glistens white. A spritz of water helps the paint stick.

Anderson connects the hose to a spigot below the turf behind the pitcher’s mound and waters the infield one last time.

Bryson Field is nearly ready, thanks to the team’s quiet efficiency.

“Everybody knows what needs to be done, when it needs to be done and how fast they need to do it for that pregame time set. Honestly, not a lot needs to be said,” Anderson said. “We don’t skip a beat out there.”

Ryan Anderson sprays while Sammy Jermane and Chris Rinebold prevent the hose from marring the infield surface. (Jon Gardiner/UNC-Chapel Hill)

3:53 p.m.

The crew is off the field. Time to play ball.

During the game, the crew hangs in the shop. Anderson comes out occasionally to see how the field is playing. “I want to check the mound and make sure that ground balls going through that grass-to-dirt transition aren’t bouncing weird.”

At the end of the fifth inning, the crew drags the infield and levels base areas. Anderson and Rinebold stay until the game ends — this one at 6:36 p.m. with a 6-4 Carolina win.

The last task is all Anderson’s. He floods the infield for a base layer of moisture the next day.

Another 12-hour workday is in the books — executed with perfection.

With their pre-game work completed, crew members rest a bit while and watch a TV broadcast showing coaches and umpires meeting just before first pitch. (Jon Gardiner/UNC-Chapel Hill)

Hear an audio description of the video.