Tiny tools: Ferrules keep us cool

These inexpensive pieces of plastic-covered metal prevent electrical failure in Carolina’s chilled water plants.

In this series, The Well looks at a variety of tiny tools that Carolina staff and faculty use in their work, each tool’s function and its importance.

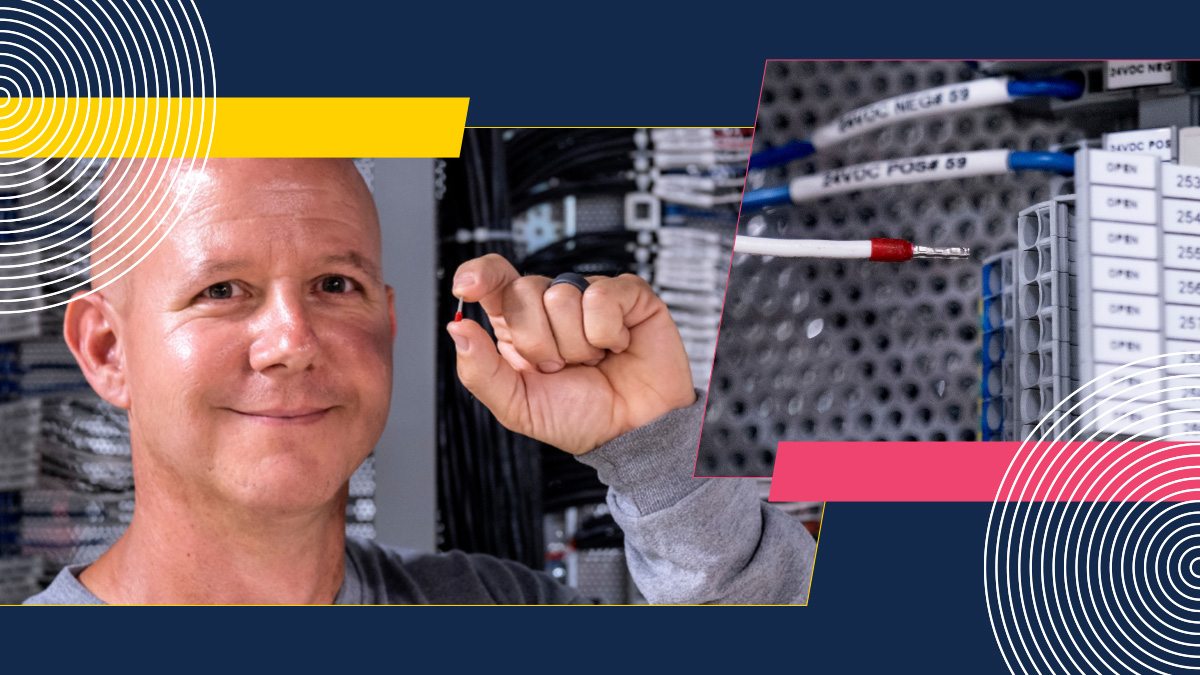

Employee: Nathan Heafner, electronics technician, chilled water department, Energy Services

Tool: ferrule, 1 mm (.039 inch) diameter, 14 mm (0.55 inch) long.

Heafner describes the ferrules that he uses as “tiny pieces of metal with colored plastic on them,” but they play a large role in the cooling of campus buildings.

Carolina’s four chilled water plants pump out 42-degree water across campus. The water returns to the plants at approximately 57 degrees. “Each chiller plant and all buildings have PLCs, or programmable logic controllers, with small control wires that go to them. On the end of each wire is where we crimp the ferrules.”

Without the protection of the little tubes of tin-plated copper insulated by plastic, thousands of electrical connections on each panel would be less secure and subject to wear and tear on the electrical wiring. “Each ferrule secures the electrical connection and protects the wires from being cut when I tighten a screw that clamps each wire to the terminal block. They also protect wires from mechanical vibrations that can wear a wire clean through.”

It only takes one damaged wire to impede a chiller plant’s operation.

Heafner’s use of ferrules is project-based. For the north chiller upgrade in winter 2022, he crimped nearly 4,000 ferrules on the facility’s newly constructed distributed control systems panel.

The ferrules come in bags of 500, sized and colored according to wire gauge. When he needs to add or replace a ferrule, Heafner reaches into what he calls his “termination bag” of ferrules and panel-wiring supplies.

“I’m a firm believer in making things as good as possible. It’s a small, inexpensive piece and well worth the additional time that it takes to connect them. Without it, you run the risk of having a failure on that wire.”